Canned Foods Remain An Essential Part Of The Food Landscape

But Where Did It All Start?

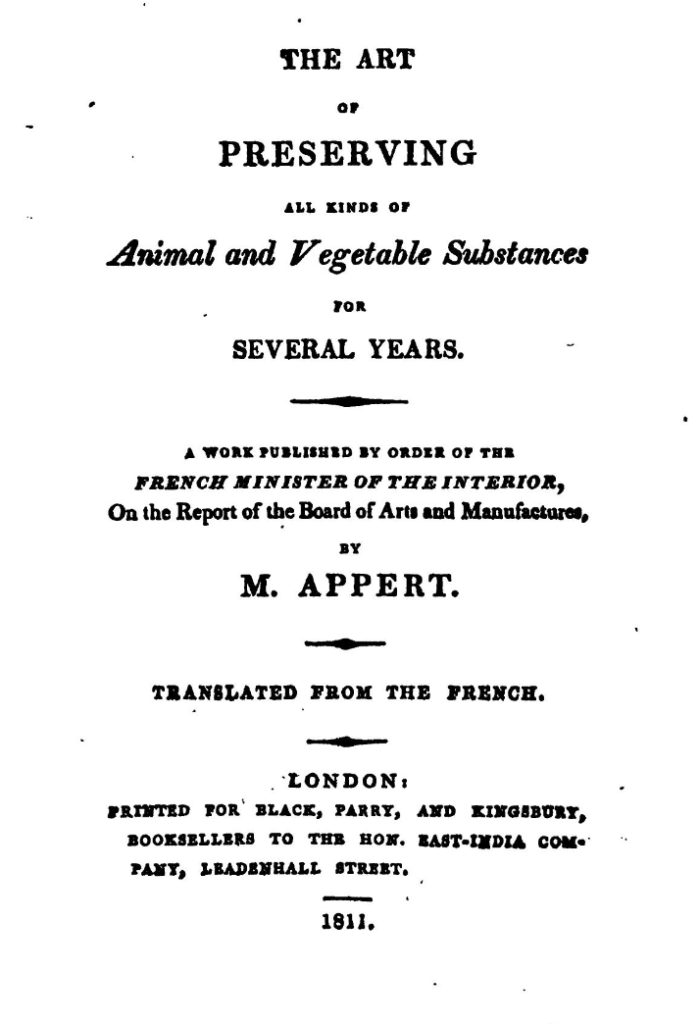

As strange as it may seem, the act of war precipitated the need for safe, long-term storage of food. Until canning came along during the Napoleonic Wars, limited food availability had caused military campaigns to be held primarily in the summer and autumn. In 1795, the French government offered a hefty cash award to any inventor who could devise a cheap and effective method of preserving large amounts of food for army and navy use. A French inventor named Nicolas Appert had begun experimenting with ways to preserve food, observing how cooked food sealed inside a jar did not spoil unless the seal leaked. In 1809, he presented his method of preserving all kinds of food substances in corked and wax-sealed glass jars that were then wrapped in canvas and boiled. He was awarded the French government prize in 1810 and is now referred to as the “Father of Canning.”

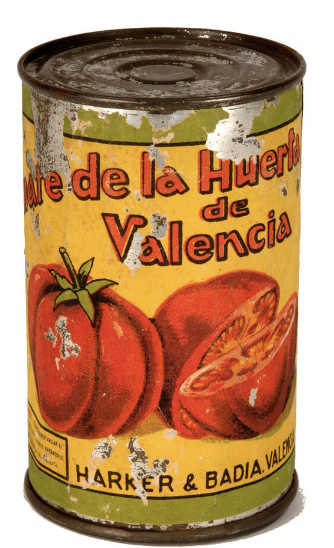

In America, the first canning factory opened in New York City in 1812, preserving oysters, meats, fruits, and vegetables using tin-plated wrought-iron cans. By the late 1800’s several wars, including the Crimean, American Civil war, and Franco-Prussian war, put canned food into the hands of thousands of soldiers. The demand for cheap, high-calorie food with a long shelf life continued to increase. Can makers began to compete with one another using highly decorated printed labels and lowering prices.

However, the process was still crude and often done in small canneries with unsanitary work environments and lacked refrigeration. It was very common for contaminated cans to slip onto the grocery store shelves.

In 1897, machinery was developed to crimp the can ends to the sides with a double seam sealed with a rubber compound. This new method used rollers to shape the can, allowing manufacturers to begin producing can bodies via sheets of coated tin plate. Rectangles were cut and curled around a die and then welded together to create the cylinder with a side seam. The top and bottom of the can were flared to create a quarter flange around the edge. Ends were die-cut, shaped, and pressed to fit snuggly on the top and bottom of the can. The body and the bottom end were brought together through a final seam by the can maker and the top end applied by the filler. In 1904, the double seam cans were in full production and dominated the market by 1911.

World War I (1916-1917)

Demand for canned food skyrocketed during World War I. Canned food such as corned beef, pork and beans, canned sausages, and stews were in high demand due to low-cost and high-calorie meals. However, after widespread dissatisfaction over the quality of the food, better-canned items started to make their way to the soldiers, including soups, ravioli, and other hearty canned meals.

150 Years of Canned History, Libby’s

The company was founded in 1869 as Libby, McNeill & Libby in Chicago, Illinois, by Archibald McNeill and the brothers Arthur and Charles Libby. The business began with a canned meat product, beef in brine or corned beef. It became well known when it began to package the meat in a trapezoid-shaped can starting in 1875. By 1880, it had 1,500 employees in Chicago, and by the turn of the century there were about 2,000 employed, by which time it had expanded to the canning of fruits and vegetables. Libby’s came under the control of Swift & Company in the 1920s. One of the best-known executives of Libby’s was Charles Scott Bridges, who in 1947 was made a director of the company and in 1953 became Libby’s president and chief executive officer. Libby’s expanded and modernized during his presidency. By 1960, Libby’s had 9,000 employees and annual revenues of $296 million and ranked 154th in size among U.S. corporations.

Libby’s was not alone

Hundreds of canneries opened all across America. among the most famous were those on the Pacific coast, near Monterey, California. The swift expansion of the Monterey fishing industry at the turn of the century gave birth to the fish canning industry and the street that would become Cannery Row. Frank Booth built the first cannery in Monterey. His rudimentary salmon cannery was located near Fisherman’s Wharf, but Cannery Row would spring up farther out of town, along Ocean View Avenue. The first major cannery on Ocean View Avenue was the Pacific Fish Company, born on February 14, 1908.

The Sardine Explosion

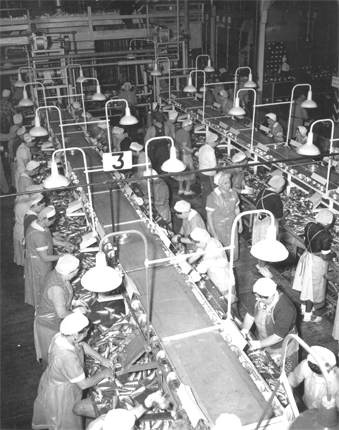

Over the next decade, fishing and canning technology improved, preparing Monterey for the huge spike in demand for canned sardines brought about by World War I. The canneries expanded rapidly, with the Row becoming a boomtown of corrugated canneries lining the rocky shore. Cannery Row’s wartime production grew from 75,000 cases in 1915 to 1.4 million in 1918. After the war, canneries continued to profit by processing odorous fishmeal. The industry slowed during the Great Depression, but World War II saw another boom for the canning industry. For a modern point of view on canned sardines, try this.

Cannery Life

Cannery workers, mostly immigrants, were called to work by cannery whistles, each with its own unique sound. The workday began with the arrival of the night catch and continued until the day’s catch was canned. The industry initially had no regulation of hours and shifts, and work in a cannery was often long, cold, smelly, and unsafe.

The Canneries Collapse

After World War II, the sardines disappeared from Monterey Bay, bringing economic disaster to Cannery Row. Before the collapse, Monterey’s fishing industry had become one of the most productive in the world due to the upwelling of cold, nutrient-rich water from the bottom of the Pacific Ocean, funneled to the surface via the vast underwater Monterey Canyon.

The area fell into ruin….but was resurrected in 1968. Two Monterey restaurant managers with strong family ties to the fishing industry and their partners were chiefly responsible for halting Cannery Row’s decay and ensuring it would forever remain a place that paid tribute to the many cultures who had made it world famous. The founding of the Cannery Row Company in 1976 began a revival of Cannery Row that transformed it from a street of burned and decrepit canneries to the number one visitor destination on California’s Central Coast.

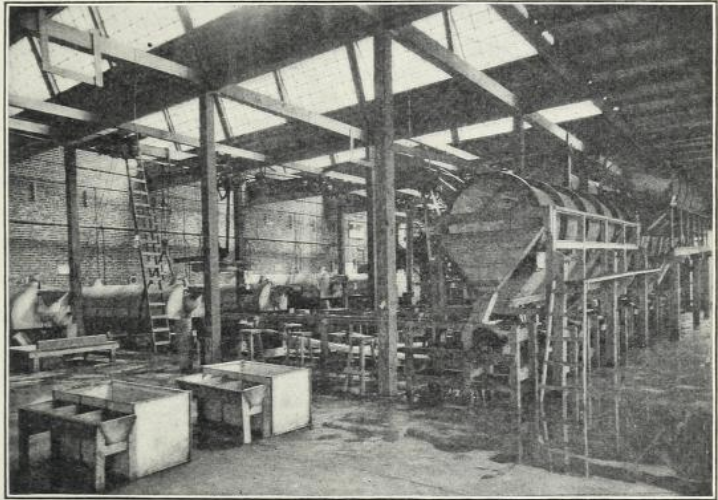

How the Early Canneries Worked

Backed onto the Monterey Bay, the earliest canneries received fish via a pier constructed far out over the coastline. Workers cut each fish by hand to remove heads and tails and then spread them to dry on wooden slats, or “flakes.” Large metal baskets of fish were then drawn through boiling peanut oil, drained, packed into cans, and soldered by hand. The final step in the process was labeling and boxing. Innovations in fishing nets and machinery soon revolutionized the fishing and canning industries, enabling mass production.

Canning today remains an important part of the distribution of our food. Frozen and refrigerated foods have become normal methods of getting food to market in fresh condition and have claimed a major part of the market. There still exists, however, a need to store foods for a long period of time and at a reasonable expense. Canning and the preservation of food serve an important need and are unlikely to go away anytime soon.

Extra Credit – See the world’s largest baked bean cannery in action!

Welcome to 3-Minutes A Day University, where you can learn a little about a lot of things every day in three minutes or less. We help you expand your knowledge and understanding of the real world, and 3-MAD University is tuition-free. Our wide-ranging syllabus includes a fascinating insight into topics including Health and Medicine, Science, Sports, Geography, History, Culinary Arts, Finance and the Economy, Music and Entertainment, and dozens more. You will impress yourself, your friends, and your family with how easy it is to learn facts and perspectives about the world around you. One topic you will never find covered is politics. We hope you enjoyed the previous three minutes. If you liked this post, please pass it along to a friend.

Was this email forwarded to you? Subscribe Here.

© Copyright 2024. 3-Minutes A Day University All Rights Reserved. Unsubscribe