How do they get that salt inside the shell?

Among America’s favorite snacks, you will find peanuts. Today, we will take a closer look at this mighty legume and reveal some things about peanuts that you likely never knew. But before we get there, I’d ask that you spend a couple of minutes watching this video.

If you grab a handful of peanuts, the chances are 99.5% that those peanuts were grown right here in the United States. Peanuts have been a valued crop since 1916, when George Washington Carver encouraged southern farmers to convert some of their cotton fields to cropland for peanuts. Now, there are about 7,000 peanut farmers in the major peanut-producing regions of the USA.

These peanut-producing states are grouped into three regions. The Southeast region (Georgia-Florida-Alabama-Mississippi) produced approximately 65 percent of all USA-grown peanuts. The Virginia-Carolina region (Virginia-North Carolina-South Carolina) accounted for nearly 13 percent of all USA-grown peanuts. The Southwest region (Texas-Oklahoma-New Mexico-Arkansas) grew more than 17 percent. Georgia is by far the largest peanut-producing state, accounting for more than half of all peanuts grown in America.

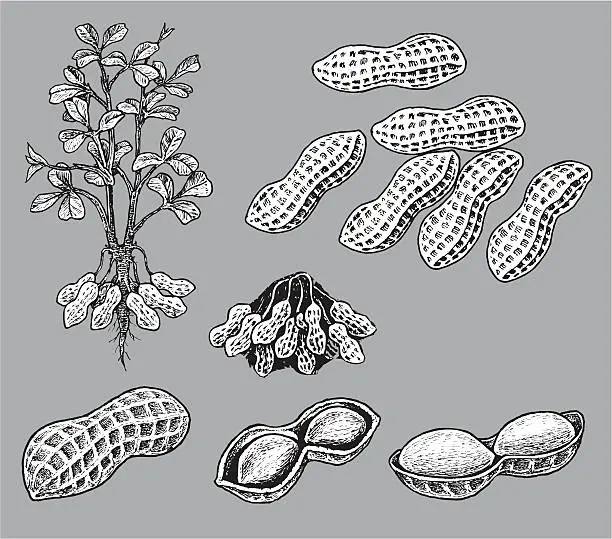

The peanut is a legume. Peanut plants have the ability to improve soil health as they’re nitrogen-fixing, which means they take nitrogen from the air and produce their own in the ground, which reduces reliance on synthetic fertilizers. They are also a sustainable crop. As peanuts are harvested, they are separated from the green, vine-like plants from which they grow. Instead of letting that organic matter go to waste, many peanut farmers use those plant byproducts as a source of fertilizer for subsequent crops. And what about the hulls – those fibrous, crunchy shells that house the kernels? Well, some companies are experimenting with the ability to turn the shells into pellets, which can be used for biofuel to produce energy, soil additives, and more!

Compared to other nuts, peanuts require significantly less water. It takes 3.2 gallons of water to grow one ounce of peanuts, but it takes more than 28.7 gallons to grow the same amount of almonds.

When peanuts are harvested, the equipment used turns the plants upside down, exposing the peanut containing root structure. The plants then set in the sun to dry for several days before another group of equipment is used to separate the shells from the roots.

Where these nuts travel from there depends on how they will be used. There are four types of peanuts grown in the United States: Runner, making up more than 80% of the peanuts grown in the U.S., runners are mostly used to make peanut butter and confections. Given that peanut butter is a pantry staple in over 90% of households, it’s no wonder that 1.3 million acres of runners were planted in 2020 across all 12 peanut-producing states. The kernels for runner peanuts are mostly uniform in size, which makes them perfect for evenly roasting so that your peanut butter has a consistent taste in every jar. Virginia is considered the “gourmet” peanut type. Virginia peanuts have large kernels and are the type you get in the shell at ballpark stadiums. Because of their large size and premium characteristics, this type is best suited for snacking instead of peanut butter. Peanuts that end up as in-shell peanuts are the biggest and prettiest. They not only have to pass grades for size, they have to pass for color. Using them in peanut butter would be a loss, like the best winemaker using his best grapes to make cheap wine.

Spanish is a smaller type of peanut compared to others. Spanish peanuts are known for their red skins and nutty flavor profile. They have a slightly higher oil content, which adds to their flavor when roasted. These peanuts are almost exclusively grown out West, in Texas, Oklahoma, and New Mexico. Spanish peanuts are typically used in candy, confections, and peanut butter, and most of the organic peanuts produced in the U.S. are of the Spanish type. Valencia, having three or more kernels per shell, has a sweet flavor and is commonly used for all-natural peanut butter. Also, they are excellent for use as boiled peanuts.

Here are some fun facts about peanuts:

From planting to harvesting, the growing cycle of a peanut takes 4 to 5 months, depending on the type and variety.

- It takes about 540 peanuts to make a 12-ounce jar of peanut butter.

- By law, any product labeled “peanut butter” in the United States must be at least 90 percent peanuts.

- Two peanut farmers have been elected president of the USA – Virginia’s Thomas Jefferson and Georgia’s Jimmy Carter.

- Former President Bill Clinton says one of his favorite sandwiches is peanut butter and banana; also reported to have been the favorite of Elvis “the King” Presley.

- There are six cities in the U.S. named Peanut: Peanut, California; Lower Peanut, Pennsylvania; Upper Peanut, Pennsylvania; Peanut, Pennsylvania, Peanut, Tennessee; and Peanut West Virginia.

- According to Little Brownie Bakers, cookie bakers use about 230,000 pounds of peanut butter per week to bake Girl Scout’s Do-si-dos and Tagalongs. Click here for a chai-spiced peanut butter cookie recipe.

- Goober—a nickname for peanuts—comes from “nguba”, the Congo language name for peanut.

- The nub between two peanut halves is an embryo. Learn more about how peanuts grow.

- The average European eats less than 1 tbsp of peanut butter a year.

- There are enough peanuts in one acre to make 35,000 peanut butter and jelly sandwiches. (Source: USDA NASS data)

Now, we will reveal the secret story behind the making of salted peanuts in the shell. According to Tom Nolan of Hampton Farms, they begin with raw (unroasted) peanuts which are loaded into 1,000-pound vats called hoppers. Then, the hoppers are filled with a simple brine made from water and salt (about 1% to 2% salt by weight—the exact amount is a trade secret). Once the hoppers are full, a vacuum pump is applied for about a minute, which pulls all of the air out of the hopper. As the air is sucked out of the peanuts, the salty brine gets pulled inside the shells (physics class flashback). The process is repeated one more time to ensure that the brine has entered all of the peanut shells.

The brine is then drained from the peanuts, and next, the peanuts go into a dryer, where the water evaporates, leaving behind a light coating of NaCl (a.k.a. sodium chloride, a.k.a. salt) on the peanuts inside the shell. After about 20 minutes in the dryer, the peanuts are dry roasted to add that toasty flavor we all associate with peanuts, which takes about another 25 minutes. In all, it takes just about an hour to complete this entire in-shell peanut-salting process. Then, they make their way to a ballpark near you.

The National Peanut Board was a source for much of the information I’ve posted here. Check them out to hear how they are funding the fight against childhood peanut allergies.

Was this email forwarded to you? Subscribe Here.

© Copyright 2024. 3-Minutes A Day University All Rights Reserved.Unsubscribe